Agro Naturtáp Kft. started its activities in 2011 with the aim of bringing modern organic fertilizers in all areas of plant production back to the important place to which they belong.

Our goal is to introduce and spread the concept of ecological nutrient replenishment - or rather the restoration of soil strength – to both our distributors and end users. We would like to meet the needs of plant growers, gardeners and ornamental plant growers of the highest quality with a view to sustainable development. That is why we strive to compile our product range in such a way that, thanks to our experienced, professional and practical consultants, we provide the best and most cost-effective solutions for traditional, integrated and ecological plant production. Among other things, we also distribute garden substrates and decorative items. We strive for our concept of production to be greener and environmentally friendly with economical technology, to achieve high nutritional values. Company using such a unique technology in its production is the Italian company FOMET SpA.

The company began producing organic fertilizers in the village of Roverchiara in 1963, exclusively from moist manure, in powder form, and later in 1972 moved to a new 5-hectare plant to meet growing demands and production.In 1976, Fomet SpA begun to use a new unique technology that neutralizes air and odors, it began producing fertilizer in the form of pellets. When processing and developing products, the goal of FOMET SpA has always been the application of natural methods and systems in the industrial area.

Methods such as extraction of controlled organic matter from selected manure, several months of controlled fermentation and humification processes in a closed environment. This concept, which the company is constantly guided by, provides the soil with a uniform nutrient supplement (taking into account plant growth) adapted to the basic needs of the soil. Over the years, thanks to this concept, the product range has expanded with new organic substances and fertilizers, while their reliability remains guaranteed. Since 1973, it has been the largest company producing pelleted fertilizers, where, in addition to the production of its own products, the company also pushes for constant development.

Fomet SpA has set up its own laboratory in order to continuously monitor the production of its products, so it can quickly evaluate all test results. The main tasks of the Fomet Lab laboratory:

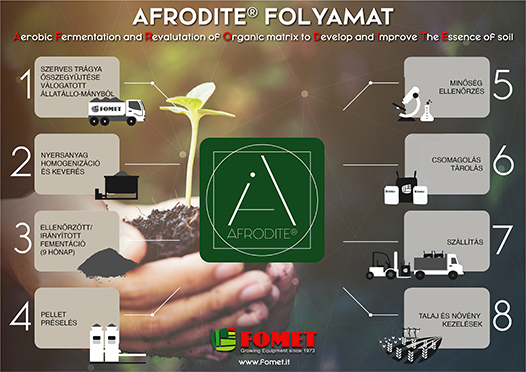

By applying the AFRODITE® process, FOMET produces fertilizers that come from manure gained through local farms (cattle, poultry and horses).

Organic 4 Agro Kft. is a manufacturer operating since 2017. Our company has an ever-expanding range of products in the field of gardening substrates, garden decorative items, organic fertilizers and bio-organic fertilizers, which it produces using domestic and international raw materials.

More information